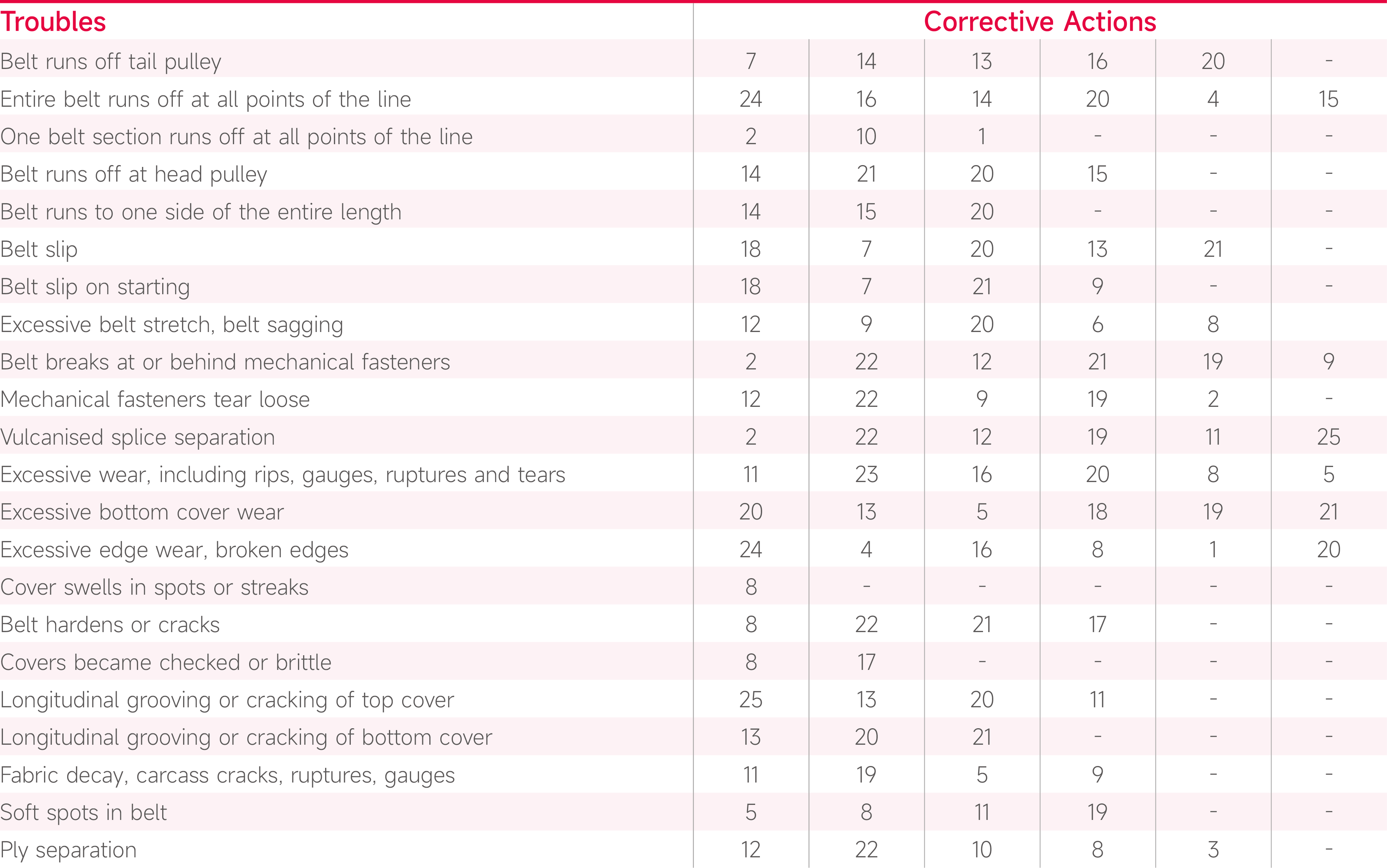

1.Belt bowed.

Avoid telescoping belt rolls or storing in damp locations. A new belt should straighten out when "broken in" or it must be replaced.

2.Belt improperly spliced or wrong fasteners

Use correct fasteners. Retighten after running for a short while. If improperly spliced, remove belt splice and make new splice. Set up regular inspection schedule.

3.Belt speed too fast

Reduce belt speed.

4.Belt strained on one side.

Allow time for new belt to "break in". If belt does not break in properly or is not new, remove strained section and splice in a new piece.

5.Breaker strip missing or inadequate

When service is lost, install belt with proper breaker strip.

6.Take-up tension too high

Recalculate tension required and adjust take up accordingly. Reduce take-up tension to point of slip, then tighten slightly.

7.Counterweight too light

Recalculate weight required and adjust counterweight or screw take-up accordingly.

8.Damage by abrasives, acid, chemicals, heat, mildew, oil. -

Use belt designed for specific condition. For abrasive materials working into cuts and between plies, make spot repairs with cold patch or with permanent repair patch. Seal metal fasteners or replace with vulcanised step splice. Enclose belt line. for protection against rain, snow, or sun. Don't over-lubricate idlers.

9.Drive underbelted

Recalculate maximum belt tensions and select correct belt. If line is overextended, consider using two-flight system with transfer point. If carcass is not rigid enough for load, install belt with proper flexibility when service is lost.

10.Edge worn or broken

Remove badly worn or out-of-square section and splice in a new piece.

11.Excessive impact of material on belt or fasteners

Use correctly designed chutes and baffles. Make vulcanized splices. Install loading idlers. Where possible, load fines first. Where material is trapped under skirts, adjust skirtboards to minimum clearance or install cushioning idlers to hold belt against skirts.

12.Excessive tension

Recalculate and adjust tension. Use vulcanised splice within recommended limits.

13.Frozen idlers. - Free idlers.

Lubricate. Improve maintenance. (Don't over-lubricate)

14.Idlers or pulleys out-of-square with centre line of conveyor

Realign. Install limit switches for greater safety.

15.Idlers improperly placed

Relocate idlers or insert additional idlers spaced to support belt.

16.Improper loading, spillage

Feed should be in direction of belt travel and at belt speed, centered on the belt. Control flow with feeders, chutes and skirtboards.

17.Improper storage or handling

Refer to storage and handling tips.

18.Insufficient traction between belt and pulley

Lag drive pulley. In wet conditions, use grooved lagging. Install correct cleaning devices for safety. See item 7, above.

19.Material between belt and pulley

Use skirtboards properly. Remove accumulation. Improve maintenance.

20.Material build-up

Remove accumulation. Install cleaning devices. Improve housekeeping.

21.Pulley lagging worn

Replace worn pulley lagging. Use grooved lagging for wet conditions. Tighten loose and protruding bolts.

22.Pulleys too small

Use larger diameter pulleys.

23.Relative loading velocity too high or too low

Adjust chutes or correct belt speed. Consider use of loading idlers.

24.Side loading

Load in direction of belt travel, in center of conveyor.

25.Skirts improperly placed

Install skirtboards so that they do not rub against belt.

+86-532-66738109

frank@bestfriendrubber.com

isabella@q-mh.com

Copyright © 2023-2024 QMH-Qingdao Quality Material Handling Co.,Ltd. Record number:鲁ICP备19015210号

Technical Support::WDL